News

How is Input Joinery Powering a Sustainable Future in UK Manufacturing?

25 Sep 2025At Input Joinery, we manufacture high-quality timber windows, doors and staircases, and we’re proud to be setting the standard for sustainable timber joinery manufacturing. We’ve made major investments in clean energy systems, smart factory technology and eco-conscious materials, all with the goal of reducing our environmental impact while producing premium, long-lasting products.

Sustainability is not just a box we tick; it’s embedded in everything we do. If you’re looking for a British joinery company that’s serious about green manufacturing, energy efficiency and low-carbon operations, here’s how we’re leading the way.

1. Solar Panels to Power the Whole Factory

We’ve installed over 620 solar panels on-site, generating up to 280 kW of power per hour using 8 high-efficiency inverters. This state-of-the-art solar energy system powers our entire factory, allowing us to operate using 100% clean, renewable energy on most days. Not only does this significantly reduce our reliance on grid electricity, but it also helps lower our carbon footprint in a big way.

Even better, on sunny days when we generate more energy than we use, we export the surplus back to the UK national grid, actively supporting the country’s transition toward greener energy infrastructure.

Key benefits:

- Factory powered entirely by solar energy during peak hours

- Lower electricity bills and reduced reliance on fossil fuels

- Carbon emissions have been significantly reduced

- Excess power is exported to support the UK energy grid

2. EV Chargers for Staff and Visitors

We know that sustainability isn’t just about what happens inside our workshop; it’s also about how our team and our customers get to and from our factory. That’s why we’ve installed four on-site EV charging points, fitted with three-phase fast charging capabilities. These are available for both our team and visiting customers or suppliers to use.

By making EV charging accessible, we’re helping to encourage cleaner commuting and doing our part to reduce the emissions associated with transport, a major contributor to global carbon output.

Why we installed them:

- Supports the shift toward electric vehicle use

- Makes clean commuting more accessible for our team

- Adds convenience for staff and visitors

- Helps reduce transport-related emissions

3. Smart Air Extraction System (2023 Upgrade)

In 2023, we upgraded our ventilation setup with a Smart Air Extraction System designed to optimise both energy use and indoor air quality. Unlike older systems that run continuously, ours operates only when needed, thanks to intelligent sensors that monitor factory conditions in real time.

The system uses automated dampers and variable speed motors to precisely control airflow across different areas of the factory. That means we’re only using as much energy as is necessary, resulting in major efficiency gains without compromising air quality.

Because it regulates itself so well, this system also reduces wear and tear on ventilation components and cuts down on electricity use for fans and motors, an improvement that’s both practical and eco-friendly.

Why it works for us:

- Only operates when needed, with no unnecessary energy use

- Dampers and smart motors optimise airflow efficiently

- Significantly cleaner air in workspaces

- Reduces strain on the electrical system, saving even more power

- Contributes to a safer, healthier factory environment

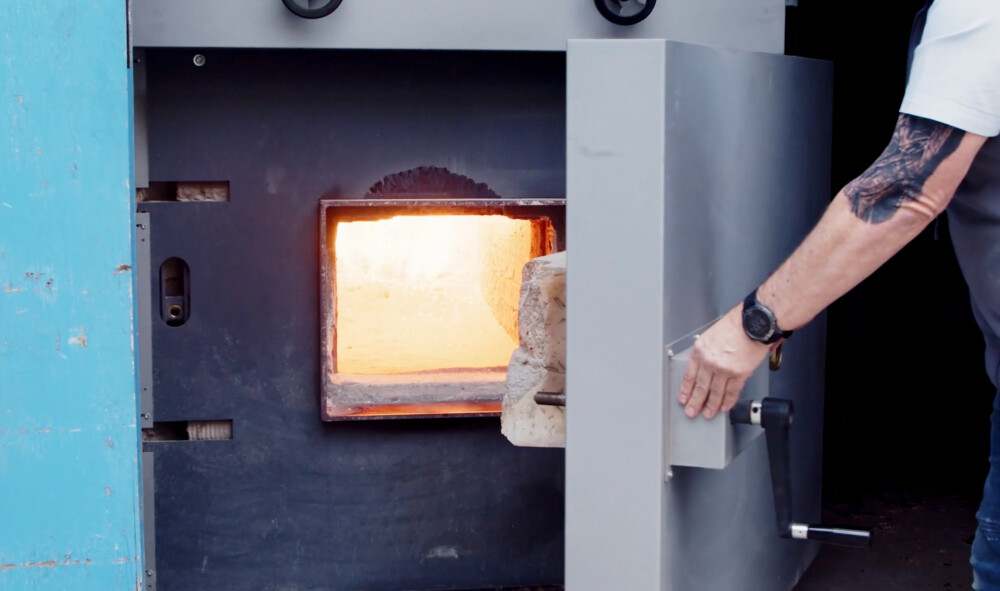

4. Biomass Boiler System (Since 2020)

Back in 2020, we replaced our older boiler with a high-tech biomass heating system and it’s been one of our most impactful upgrades. This system makes us completely self-sufficient for heating. It works by burning our own wood waste, which is created as a natural by-product of our manufacturing process.

Instead of sending this material to a landfill, we give it a second life by using it to heat our entire facility. It’s a perfect example of a closed-loop system where waste becomes fuel.

Why it works for us:

- Full heating self-sufficiency with no need for external energy sources

- All wood waste is reused on-site

- Zero-waste heating with no landfill contribution

- Eliminates emissions from traditional fossil-fuel heating

Sustainable Materials and Product Design

Our commitment to sustainability doesn’t stop with our factory; it’s built into every product we manufacture. We use timber, a renewable and responsibly sourced material, which has far less environmental impact than alternatives like uPVC.

We carefully select certified timber, ensuring that our raw materials come from sources that promote reforestation and biodiversity. Every product we make is made to measure, meaning we reduce off-cuts and material waste while also improving energy performance once installed.

We also incorporate high-performance double glazing into our windows and doors as standard, helping homeowners and builders reduce heat loss and lower energy bills.

Why our products are greener:

- Responsibly sourced timber with a low carbon footprint

- Made-to-measure manufacturing minimises waste

- High-efficiency glazing improves insulation

- Long-lasting products mean less need for replacements

- Timeless designs ensure durability across decades

Made in Britain with Lower Environmental Impact

All our products are proudly manufactured in Britain, right here at our Hampshire facility. By keeping everything local, we eliminate the need for long-distance transport from overseas suppliers. That not only cuts down on fuel emissions, but it also shortens our supply chains, leading to faster delivery times and more consistent product quality.

Supporting UK manufacturing also means supporting the local economy and skilled jobs in the community, which we believe is another important part of long-term sustainability.

Why UK-made matters:

- Reduced emissions from international shipping

- Better quality control from start to finish

- Faster turnaround and delivery

- Supports the British economy and local jobs

Why Choose Input Joinery?

Sustainability and craftsmanship go hand in hand at Input Joinery. From solar-powered production and smart factory upgrades to zero-waste heating and eco-friendly materials, we’re proving that traditional British joinery can be both beautifully made and sustainably built.

If you’re looking for a joinery partner who values quality, innovation and the environment, we’d love to hear from you.

What we offer:

- Solar-powered production

- Smart, energy-saving systems

- On-site EV charging

- Zero-waste heating via biomass

- Eco-friendly timber joinery

- High-performance double glazing

- Fully bespoke made-to-measure joinery

- British-made products with a lower environmental impact

Explore Input Joinery or get in touch to learn more about how we’re bringing sustainability to life, one product at a time.